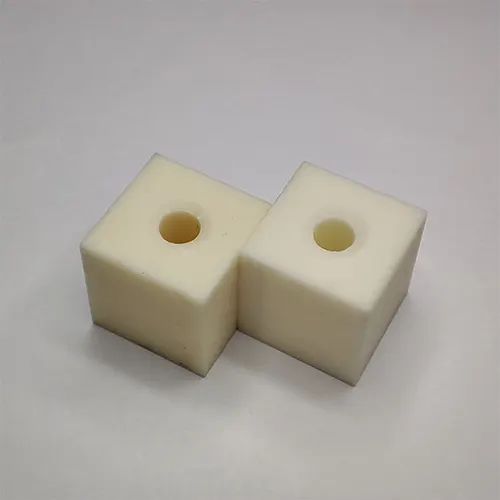

99.99% Alumina Ceramic

99.99% alumina ceramic is centered on an ultra-high-purity alumina matrix, achieving atomic-level dense structures through ultra-high-temperature sintering processes. Its hardness rivals that of natural single-crystal corundum and exhibits ultra-high-temperature stability in extreme inert or vacuum environments. The material possesses zero-porosity impermeability, resisting erosion from molten metals, plasma, and highly corrosive media, while boasting ultra-low dielectric loss and sub-nanometer surface smoothness, making it ideal for high-precision optical and electronic device fabrication. Its unique biocompatibility and non-magnetic hysteresis effects enable critical applications in deep-space probe radiation shielding layers and superconducting system insulation components. It also plays an irreplaceable role in quantum technology, semiconductor lithography, and other cutting-edge fields, representing the pinnacle of industrial ceramic performance and manufacturing technology.

FAQ

Precision ceramics offer superior high-temperature resistance, corrosion resistance, wear resistance, and insulation, making them ideal for extreme conditions like high temperatures and high pressure. They also support higher precision processing, meeting complex design needs.

Precision ceramics are widely used in aerospace, automotive, electronics, medical, and industrial equipment industries, especially in applications requiring high performance and durability.

Precision ceramics are challenging to machine due to their high hardness and brittleness. Special equipment and processes, such as CNC machining, are required to ensure precision and surface quality.

When selecting a ceramic material, it is essential to consider specific working environments and performance requirements, such as high-temperature resistance, corrosion resistance, and mechanical strength. Different applications require ceramics with varying properties.

Precision ceramics generally have a long lifespan, with their longevity ranging from several years to even longer, depending on the usage environment (such as temperature, pressure, wear, etc.).

- PREV: 99.9% Alumina Ceramic

- NEXT: Gemstone