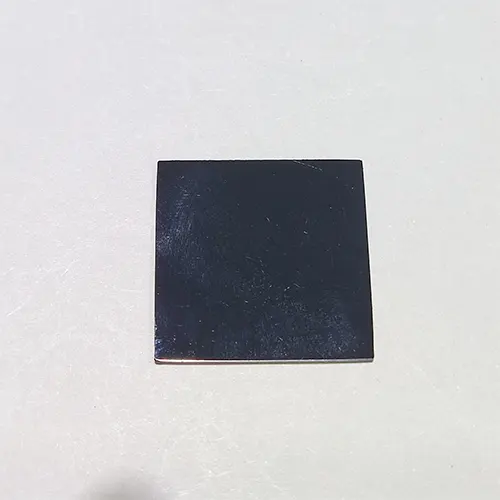

Aluminum Nitride

Aluminum nitride is distinguished by ultrahigh thermal conductivity (70-200 W/m·K), excellent electrical insulation, and low thermal expansion coefficient (matched to silicon). It also demonstrates high-temperature stability (heat resistance up to ~2200°C), low high-frequency signal loss, and plasma erosion resistance, ensuring reliable performance in extreme environments. Additionally, its chemical inertness makes it resistant to strong acids and alkalis, enabling long-term reliability in high-frequency/high-voltage, high-temperature/corrosive, or high-power-density applications.

Key applications of aluminum nitride include high-power LED heat dissipation substrates, semiconductor packaging interposers, RF/microwave components, power electronics modules (such as IGBT substrates), laser diode heat sinks, and nuclear reactor components. Often referred to as the “core ceramic for advanced electronic packaging,” aluminum nitride plays an irreplaceable role in 5G communications, new energy vehicle powertrains, advanced packaging technologies, and extreme thermal management systems.

FAQ

Precision ceramics offer superior high-temperature resistance, corrosion resistance, wear resistance, and insulation, making them ideal for extreme conditions like high temperatures and high pressure. They also support higher precision processing, meeting complex design needs.

Precision ceramics are widely used in aerospace, automotive, electronics, medical, and industrial equipment industries, especially in applications requiring high performance and durability.

Precision ceramics are challenging to machine due to their high hardness and brittleness. Special equipment and processes, such as CNC machining, are required to ensure precision and surface quality.

When selecting a ceramic material, it is essential to consider specific working environments and performance requirements, such as high-temperature resistance, corrosion resistance, and mechanical strength. Different applications require ceramics with varying properties.

Precision ceramics generally have a long lifespan, with their longevity ranging from several years to even longer, depending on the usage environment (such as temperature, pressure, wear, etc.).

- PREV: Silicon Carbide

- NEXT: Null