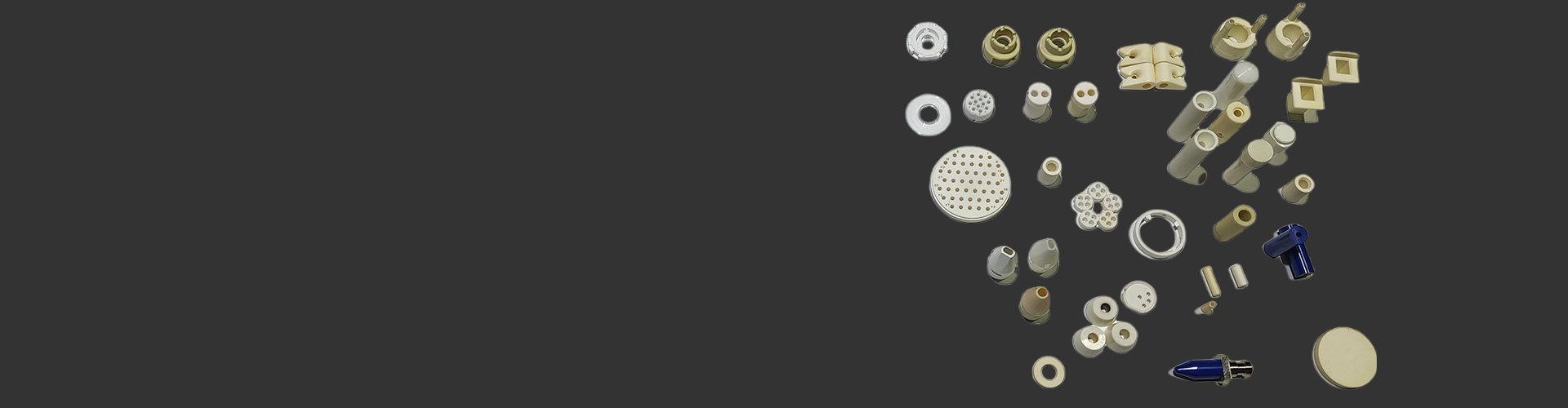

Other Custom Structural Components

In addition to standard products, we can customize various types of ceramic structural components according to customer requirements, including complex geometries, extreme tolerance control, and special material combinations, to meet the needs of aerospace, semiconductor, medical equipment and other demanding industries.

We specialize in high-precision ceramic custom processing, providing a variety of complex shapes and special functions of ceramic parts, widely used in machinery, electronics, semiconductors, medical, chemical and other industries.

Our custom parts include:

- Bushings and nozzles - wear-resistant and corrosion-resistant, suitable for high-precision fluid control.

- Square punched holes, metallized - suitable for electronic and electrical insulation applications.

- Engraving and printing, metal bonding parts - achieve a firm bond between ceramics and metal and improve structural strength.

- Special-shaped ceramic parts——according to customer needs, precision processing of various non-standard ceramic structural parts.

We use advanced molding, sintering and precision processing technologies to ensure that our products meet the industry requirements of high wear resistance, high insulation and high precision.

| Size Capability Range | ||

| project | Shape | Maximum / minimum size |

Length Range |

Tube | ≤1000mm (some materials ≤100mm) |

| Great | ≤1000mm (some materials ≤100mm) | |

| plate | ≤400×400mm (some materials ≤100×100mm) | |

| Special-Shaped Structural Parts | ≤300mm | |

Outer Diameter Range |

Tube | ≤150mm |

| Great | ≤150mm | |

| plate | ≤400×400mm (some materials ≤100×100mm) | |

| Special-Shaped Structural Parts | ≤150mm (some materials ≤50mm) | |

Inner Diameter Range |

Through Hole | ≤200mm (some materials ≤50mm) |

| Blind Via | ≤50mm (some materials ≤10mm) | |

| Step Hole | ≤50mm (some materials ≤10mm) | |

| Ball Diameter Range | - | ≤100mm (some materials require introduction) |

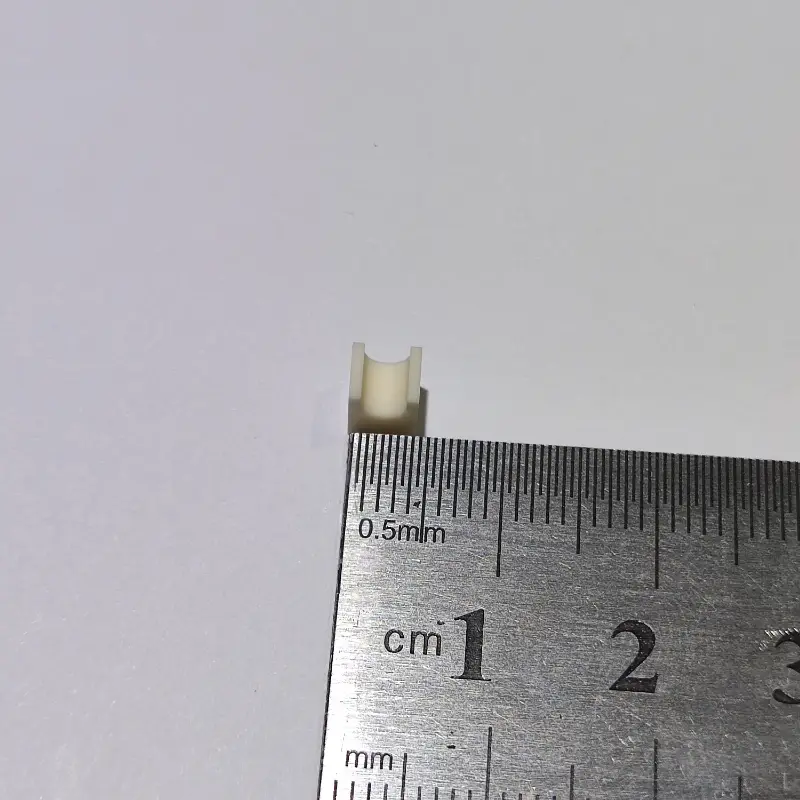

| Minimum Wall Thickness | - | 0.1 – 0.2mm (depending on material) |

| Minimum Hole Diameter | - | ≥0.4mm |

| Thread | - | ≥Φ2mm |

| Minimum Root Cleaning | - | R0.1mm |

| Processing Accuracy | |

| Project | Accuracy |

Outer Diameter Accuracy |

1-25mm: ±0.002mm 20-50mm: ±0.003mm 50-100mm: ±0.050mm 100-150mm: ±0.020mm |

Inner Diameter Accuracy |

0.5-3mm: ±0.001mm 3-10mm: ±0.005mm 10-30mm: ±0.01mm 30-100mm: ±0.05mm 100-150mm: ±0.10mm |

| Length (Thickness) Accuracy | ±0.005mm |

| Ball Accuracy | ±0.002mm |

| Machining Accuracy of Special-Shaped Structural Parts | ≤0.03mm |

| Surface Roughness | Ra0.04 – Ra0.2 |

| Geometric Tolerance | |

| Project | Accuracy (depending on product structure) |

| Roundness | 0.002mm |

| Concentricity | 0.002mm |

| Straightness | 0.006mm |

| Verticality | 0.005mm |

| Parallelism | 0.003mm |

| Flatness | 0.005mm |

Note: Due to the wide range of indicators, there are correlations between different data. The above data is for reference only. You are welcome to provide specific drawings and requirements. We will evaluate the cost and delivery time for you as soon as possible!

If you have any needs for ceramic tubes, please do not hesitate to contact us immediately !